Change Language :

Ball bearing wiki: Technical information about ball bearings

White papers

Performance features of ball bearings made from high-performance plastics

System and functional integration for polymer ball bearings

Ball transfer units made of plastic: A promising alternative to metal

Seven tips for selecting the optimum conveyor roller for your application

Should ball bearings be greased?

As a rule, conventional ball bearings made of metal rely on external lubricants. But can they work without? Our plastic ball bearings are the best proof that they also work without grease.

Ball bearing sizing table information

In this table you will find our most common plastic ball bearing sizes. If you cannot find the right product, we will be happy to fulfil your request with our special part service.

Test laboratory for ball bearings

Our ball bearings are put through their paces. Years of research in our test laboratory have made our xiros plastic ball bearings superior to metal versions in many respects.

Questions about ball bearings

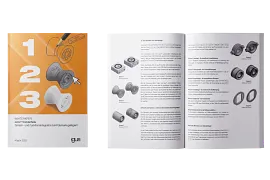

1. Housing (tolerance H7)

2. Front side (balls visible)

3. Rear side (cage visible)

4. Press-fit the ball bearing with the front side first

5. Install shaft (tolerance h6) with chamfer

6. A locating spigot must be provided

If the metal ball bearing is a fixed or floating bearing, the outer and/or inner race is firmly connected to the shaft or housing. The easiest way to attach this type of bearing is by press-fit. However, this requires certain tolerances in the dimensions of the shaft and housing. In general, it can be assumed that the rotating race is designed with a tight fit, a so-called interference fit, and the stationary race is a loose fit, which is a clearance to press fit. If there are impacts on the bearing, both the rotating and stationary races are designed with a tight fit. Easy assembly and disassembly of the bearing and the prevention of race rotation is essential. Furthermore, the inner race can also be pressed with a clamping sleeve or clamped between a nut or clamping screw.

In the thermal process, also known as shrink-fitting, the metal ball bearing is usually heated to a temperature of up to 125°C by induction. As a result, the entire bearing expands and can easily be pushed onto the cold shaft. Once the ball bearing has cooled down, it contracts, resulting in an extremely tight fit on the shaft.

But how do you fasten/install and measure the xiros plastic ball bearing? We are one of the few manufacturers in the world to produce ball bearing races using injection moulding. This offers users the following advantages:

- High wear resistance due to moulding under high pressure

- Homogeneous material distribution

- Cost-effective production, therefore also favourable prices

- Simplification of ball bearing installation

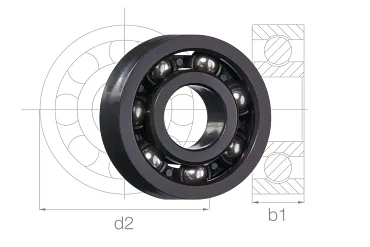

Due to this manufacturing process, different rules apply for both measurement and fixing compared to metallic or ceramic ball bearings. The outer race of the plastic ball bearing is conical. This simplifies installation in the intended housing (with the narrow side first). The bearing clearance is reduced after the press-fit into an H7 housing. Therefore, the ball bearings must be measured over the entire width, starting from 90° to the injection point.

Ball bearing replacement required: Defective metal ball bearing for an automatic car gearbox

Replace the ball bearing? This should be done when ...

- the bearing clearance caused by the wear has reached an unacceptable level, for example when the shaft "slags".

- the cage is worn and threatens to fall out.

- the bearing races are broken due to excessive impact forces.

- the running surfaces of the bearing races are visibly damaged.

- the ball bearing is blocked, for example due to coarse dirt.

- the balls (glass) are broken.

- "unprecedented noise emissions" occur.

- no more bearing clearance exists due to deposits on the balls.

For our plastic ball bearings, however, this does not always mean that a new bearing has to be fitted.

If there is a blockage due to heavy dirt accumulation, it may be possible to rinse or blow out the ball bearing and it can continue to be used. This applies if there is no damage to the bearing races and balls.

The wear limit is defined by each customer depending on the field of application. For applications that require high precision or positioning accuracy, maintenance intervals should be shorter. For users who utilise e.g. xiros conveyor rollers, a higher level of acceptance may apply, as only simple deflection tasks need to be performed.

Our polymer ball bearings have an inherent radial bearing clearance of approximately 0.05 to 0.15mm. They owe this characteristic to their smooth running and low breakaway torque. The open design also makes them very easy to clean.

WALK-IN with xiros plastic ball bearings

SNAP-IN bei xiros Kunststoff-Kugellagern

Ball bearings consist of an inner and outer race, a cage and rolling elements. The cage is there to separate the rolling elements, in the form of balls, from each other. If the balls were not separated, they would run against each other and overheat. This would have destructive effects at high rotational speeds and friction of the balls. But how do the balls get into the ball bearing?

Option 1:

This question is easy to answer when looking at a deep groove ball bearing according to DIN 625, as these have noticeable indentations on the inner and outer race. If the inner and outer races are moved towards each other up to the respective recess, the balls can easily be filled into the grooves and fixed with the cage. In this case, the cage takes over the function of preventing the balls from falling out.

Option 2:

Heating the outer ring and cooling the inner ring for smaller metal bearings down to miniature designs is also unusual, but practised in the industry. The balls and cages can then be easily inserted into the space created between the inner and outer race. If the materials of the race contract or expand again, the ball bearing has reached its standard dimensions and all the balls are in place. For igus, only the first option comes into question, but there are also others, which are illustrated below.

Many metallic rolling bearings are available in a sealed version. Ball bearing seals are generally mandatory for the metallic version, as otherwise contamination can combine with the lubricant and thus block the running of the bearing. Should the ball bearing be open or closed? This depends on the ball bearing type.

Metallic bearings must be protected:

Metallic ball bearings are also available as open types. However, these are only used very rarely due to the problems mentioned above. Therefore, a dusty environment is sufficient to negatively influence the running properties over a longer period of time.

Metallic ball bearings are sealed according to the shaft seal principle. These seal designations are possible:

- Z = one-sided sheet metal cover disc with gap seal

- ZZ/2Z = as above, from both sides

- RS = single-sided, sliding rubber seal

- LB = as above

- 2RS = as above, from both sides

- LLU = as above, non-contact rubber seal, from both sides

- EE = as above, from both sides contacting, abrasive

- RZ = one-sided, non-contact rubber seal

- LB = as above

- 2RZ = as above, from both sides

- LLB = as above

The seal designations are valid worldwide and, depending on the manufacturer, usually appear as a suffix after the respective DIN installation size.

xiros plastic-ball bearing with cover disc

In our online shop, customers can choose between different types of covers. Not all of them are available for every bearing size, but a single-sided cover disc is always available. xiros plastic-ball bearing with cover disc

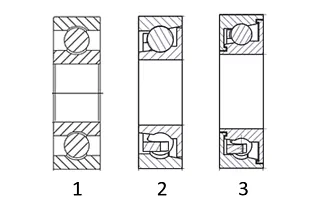

1. Open type

2. Single-sided cover disc

3. Labyrinth seal on both sides

These two types of ball bearing are usually only available as an open type. The reason for this is that these bearings need not to be lubricated. The open design has a major advantage with these materials. Any dirt that enters can easily come out again, or be flushed out or blown out with compressed air. This prevents dirt adhesion due to lubricants. igus therefore dispenses with the use of suffixes in comparison to the metallic counterpart.

Without ball bearings, the world wouldn't really turn, would it?

Because we simply see the world as it is. Everything grows and develops, is in motion and is taken for granted. However, people hardly think about such a marvel of technology: The ball bearing. We encounter it every day in our lives, whether we are travelling to work by bike, train, bus or car. There are ball bearings in all means of transport, but also in kitchen appliances, training equipment in the gym or at the bowling alley in the evening – we find rolling bearings everywhere. But what are they anyway? Since the development of the steam engine and the beginning of industrialisation, ball bearings have become an integral part of our everyday lives.

Ball bearings are bearing components that reduce the frictional resistance caused by rolling bodies between an inner race and an outer race. They are used to fix axles and shafts in place and can absorb radial and/or axial forces, depending on the type. Due to their design, they also allow the shaft or other components that are mounted on an axle, such as a wheel, to rotate.

What is a ball bearing? Quickly explained here in the video.

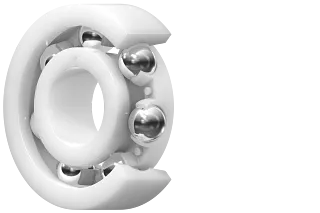

Cross section of a xiros plastic ball bearing

Inner and outer race:

The suitability of a xiros plastic ball bearing is determined by the materials of the two races. Our low-friction ball bearings are made from high-performance plastics with different material properties, allowing them to be used in a wide range of applications and maximising service life.

Ball bearing cage:

The cages of our plastic ball bearings are perfectly matched to the materials of the outer and inner races in terms of chemical and temperature resistance.

Ball bearing balls:

In addition to stainless steel balls, balls made of glass, plastic or ceramic are also used. Glass balls should be selected if freedom from metal and chemical resistance are important. Plastic balls result in exceptionally light ball bearings. The stainless steel version is particularly cost-effective and temperature-resistant.

Consulting

I look forward to answering your questions

igus Australia1300 726 244Write e-mail

Shipping and consultation

In person:

Monday to Friday from 8 am - 5 pm.