Change Language :

smart plastics knowledge base

Click on the relevant category to go to the information you need.

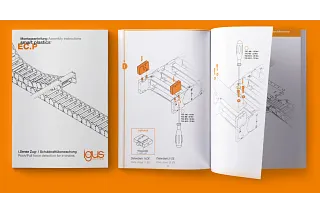

Assembly instructions

Here you will find the assembly instructions for our smart plastics systems, which give you step-by-step directions.

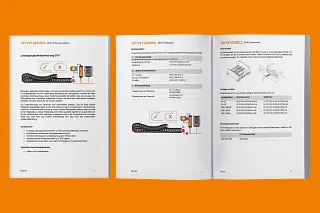

Operating instructions

In addition to the assembly instructions, there are also detailed operating instructions for all our smart plastics systems. These take you step by step through all the necessary operating elements:

- Safety instructions

- Installation

- Commissioning

- Troubleshooting

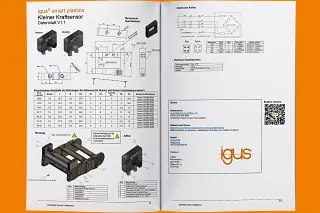

Data sheets

Below you can find all available data sheets for the individual parts included - sorted by sensor type.

Data sheets for EC.P & CF.P:

Data sheets for EC.B:

Data sheets for EC.W:

Data sheets for EC.IT:

Data sheets for TR.B:

Data sheets for modules:

System descriptions

System descriptions provide a compact overview of the advantages, areas of application and accessories of smart plastics products.

Below you will find the available descriptions for the various smart plastics systems.

Download the suitable system description here:

3D CAD portal for smart plastics

Designing intelligent energy chain systems faster. CAD models for all smart components.

Our intelligent e-chain systems are already being used reliably in many hundreds of thousands of applications worldwide - from beverage vending machines and CNC machines to steelworks. Unsupported lengths can be bridged with ease and long travels are conceivable for a wide range of industries.

CAE data: reduce project planning effort by 50% with EPLAN

Users of EPLAN solutions benefit from increased efficiency in the product development process thanks to standardised procedures, automated processes and end-to-end workflows.

Where can I find the right smart plastics data for my electrical design?

- In the EPLAN Data Portal - in the browser or your EPLAN instance

- Via our download portal under "Software"

FAQ - Frequently asked questions:

The term "Internet of Things" describes networked machines that communicate independently with each other without human intervention. An illustrative example is a refrigerator that uses sensors to detect when there is no milk left or a specified minimum quantity has been reached, and orders fresh supplies from the connected supermarket via a network. In contrast to the normal internet, where a user makes an input on an end device, the systems here act independently, machine-to-machine (M2M).

It is not always possible to foresee and prevent defects in systems. A broken energy chain, for example, the entire system - and not just the energy supply itself - can suffer damage and shut down for a long time. If, however, an EC.B breakage detection sensor is installed in the e-chain, it detects a defect such as a breakage at an early stage and either triggers a signal or shuts down the entire machine via an NC contact. The sensor thus prevents further damage and total machine failure, i.e. a "crash". Our crash prevention sensors protect machinery against major defects, failures and downtimes, ultimately avoiding unplanned costs.

Industry 4.0 is a project of the German Federal Government for the digitalisation of industrial production. The idea behind this is that production processes do not run side by side as individual processes, but are digitally networked with modern communication technology. All components such as machines, products, logistics and, of course, people communicate with each other. The goal of this digital networking is a well-integrated and efficient self-organisation of production that uses resources economically. Industry 4.0 has now become a popular term for anyone involved in digitising their business, from order entry to machine monitoring.

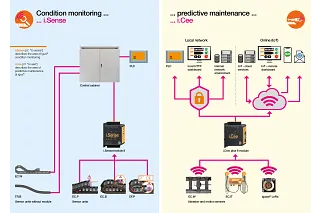

Predictive maintenance means that the ideal time for maintenance measures can be determined. This is possible when systems are equipped with sensors that report wear and use of components. Ideally, predefined operating data and real use data are compared via an IoT online connection so that the ideal time for efficient maintenance can be determined for an operation that saves costs and conserves resources.

Robust and smart - How digitally networked energy chains strengthen STS cranes in the port of Rotterdam

Download the case study

This case study clearly describes how EMO B.V. was able to achieve mileages of over 375,000 km on its STS cranes with igus chains for cranes®.

Further information material

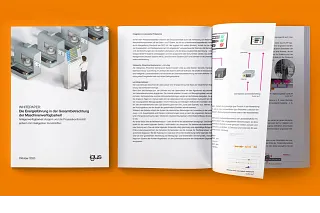

Our white papers show how you can improve energy supply for your application and thus reduce costs. Practical tips, 50 years of experience with energy chains and thousands of test results can help you select the best energy supply system.

Why intelligent motion plastic from igus?

Use

Quality: tested, proven and digitised

Thanks to intensive research and extensive testing under real-life conditions in the industry's largest test laboratory, igus guarantees a long service life. Our constantly growing expertise and the corresponding database are incorporated into the further development of our smart products in collaboration with our customers.

Test

Quality: tested, proven and digitised

Thanks to intensive research and extensive testing under real-life conditions in the industry's largest test laboratory, igus guarantees a long service life. Our constantly growing expertise and the corresponding database are incorporated into the further development of our smart products in collaboration with our customers.

Blog

Interesting articles

Find interesting articles about intelligent energy management in our blog.

smart plastics at a glance: intelligent condition monitoring and predictive maintenance

What are the advantages of igus smart plastics?

▲ Tech up

- Extension of the maximum service life

- Increase in overall system efficiency

- Integration into Industry 4.0/IIoT concepts

▼ Cost down

- Reduced maintenance costs through early warnings

- No unplanned downtimes

- Lower warehousing costs

What are successful examples of smart plastics?

smart plastics is already being used reliably in many thousands of applications worldwide - from bread-vending machines to steelworks. Over 400,000 customers across the globe from 50 industries rely on igus ... and more and more of them now also count on intelligent components from smart plastics.

Consulting

I look forward to answering your questions

igus Australia1300 726 244Write e-mail

Shipping and consultation

In person:

Monday to Friday from 8 am - 5 pm.