Change Language :

CNC machining service

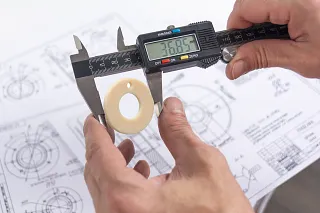

Custom CNC machining service using high-performance plastics | Fast UK service

igus® offers a CNC machining service of tribologically optimised polymers with instant feasibility checks, lifetime prediction, and delivery in as little as 10 days.

In order to be able to fulfil all customer requirements, the need for bespoke parts is essential. We have capabilities of CNC machining customer bespoke parts from our high-performance materials.

Using the online configurators customers can identify the best material for their application, confirm tolerances and give basic assistance throughout the project.

Benefit from these advantages:

► Transparent instant costing ✔️

► Automated feasibility and tolerance checks ✔️

► Predictable service life ✔️

6 reasons to choose CNC-machined plastic parts from igus

1. Lubrication-Free Operation

igus® materials contain built-in lubricants, eliminating the need for external oils—ideal for clean, low-maintenance operation in automation, medical, and food environments.

2. Chemical Resistance

igus® plastics are built to endure aggressive chemicals, ensuring reliable performance in demanding applications like lab equipment, cleaning systems, and chemical processing.

3. FDA-Compliant Materials

We offer a range of FDA-approved polymers suitable for direct contact with food and pharmaceuticals. Perfect for hygienic applications where safety and compliance are critical.

4. High Temperature Resistance

Our materials can handle continuous operating temperatures of up to 250°C, making them ideal for demanding environments like packaging machinery, automotive components, and heat-exposed systems.

5. Lightweight Design

Plastic components are significantly lighter than metal, reducing system weight, energy consumption, and wear—especially beneficial in robotics, aerospace, and mobile machinery.

6. Predictable Service Life

With our CNC machining service, you can access lifetime prediction tools to estimate wear and performance based on your application. This helps you design with confidence and reduce unexpected downtime.

igus® CNC machining standards for plastic parts

We follow precision standards tailored for plastic-compatible CNC machining to ensure fast, reliable production and accurate pricing.

Tolerances

- General tolerance: ISO 2768-mK for length, shape, and position

- Minimum achievable tolerances (DIN ISO 286)*:

- Up to 30mm: IT9/10

- 30–180mm: IT10/11

- 180–500mm: IT11/12/13

- Over 500mm: Assessed individually

Threads & surface finish

- Metric ISO threads (M) available; other types on request

- Typical surface roughness: Ra 2–3 µm, suitable for turned and milled finishes

Fast processing advantage

By adhering to these standards, we can:

- Automatically calculate pricing

- Accelerate order processing

- Save you valuable time

Our CNC design guide

Our white paper supports you with the most important principles for designing your CNC components.

You will find 12 machined parts so that you can achieve a design that is optimised for economy and production.

See these application examples for yourself:

Frequently asked questions about CNC machining

We machine a wide range of high-performance polymers, including wear-resistant, FDA-compliant, and temperature-resistant materials.

We accept common CAD formats such as STEP, IGES, and STL. Upload your file to receive an instant feasibility check.

Typical tolerances range from ±0.1 mm, depending on material and geometry. Contact us for tighter tolerance requirements.

Plastic parts are lighter, corrosion-resistant, and often more cost-effective. iglidur® materials also offer self-lubricating properties.

CNC machining stands for Computer Numerical Control machining. It’s a manufacturing process where pre-programmed computer software controls the movement of tools and machinery to shape raw material (like metal, plastic, or wood) into precise parts.

This depends on the part, the qty, the material and the complexity of the part. Usually the set up costs is divided by the number of parts so the more being machined the lower the individual costs should be. It also depends on the number of parts that you can get out of the material.

Consulting

I look forward to answering your questions

igus Australia1300 726 244Write e-mail

Shipping and consultation

In person:

Monday to Friday from 8 am - 5 pm.