Change Language :

Tolerance check

igus® manufacturing standards

Tolerances of CNC components that work with plastics

Plastic has its own characteristic behaviour, which must be taken into account during machining. Our manufacturing standards ensure that your turned and milled parts are machined to the correct plastic tolerances.

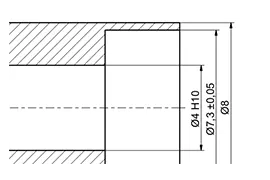

We recommend adhering to the following standards (see diagram on the right) so that your components can be produced as quickly as possible.

General and special tolerances (lengths)

Tolerances of CNC components that work with plastics

For lengths, the general tolerances according to ISO 2768 (degree "medium") are recommended as shown in the table on the left.

Tighter tolerances deviating from this are possible up to a certain ISO tolerance level. The minimum possible and recommended tolerances can be found in the table on the right (even tighter tolerances would be feasible on the part of the machine, but it would not be possible to maintain them with plastic components over time, which would make no sense from a technical point of view).

Design guide

Our white paper supports you with the most important principles for designing your CNC components. We give you 12 machined parts so that you can achieve a design that is optimised for economy and production.

Get your machined parts in three steps

You would like to have machined parts made from iglidur®

bar stock quickly and easily and calculate their price immediately online? Then use our CNC service now.

When and why CNC machining is worthwhile for your components

Large variety of materials and material quality:

The large material variety of our iglidur® bar stock guarantees you optimum tribological component properties for every application.

High surface quality:

Due to the process, CNC machining produces good surfaces - iglidur® components normally do not require any special post-processing for their sliding surfaces either.

Precise component dimensions with tight tolerances:

You receive dimensionally accurate components with tight tolerances and fits. Narrow tolerance widths (up to tolerance grade 9 in accordance with DIN ISO 286) are usually feasible. Tolerance widths of 0.05mm are therefore no problem.

Economical for small to medium quantities:

CNC machining is often the most economical process for two to four-digit quantities, especially for large-volume parts with simple geometries.

Consulting

I look forward to answering your questions

igus Australia1300 726 244Write e-mail

Shipping and consultation

In person:

Monday to Friday from 8 am - 5 pm.