Change Language :

Durable components for plastic processing machines

When we talk about high‑performance plastic components for plastics‑processing machinery, we speak from direct experience. In our own production and monitoring systems—customised in‑house to meet demanding requirements—we rely on our e‑chains®, maintenance‑free plain and linear bearings and durable cables, often running continuously in three‑shift operation.

Across plastics processing, treatment, recycling and process‑automation equipment, igus® components deliver long‑lasting, lubrication‑free performance. They resist dust, dirt and moisture, ensuring reliable operation even in harsh environments. Their low weight also helps reduce overall machine mass and associated operating costs, including energy consumption.

igus® products suitable for plastic processing machines

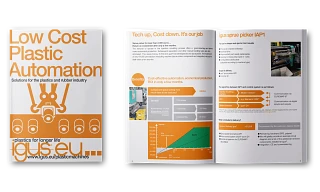

Smart production with igus® Low Cost Automation

With our LCA products, you can easily adapt your automation processes and therefore react flexibly to new developments.

All products developed by igus® for automation are used in many of our own production applications.

Plastics processing machinery technology

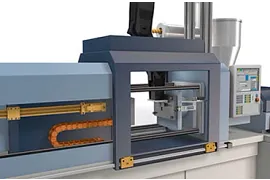

Injection moulding machines

Fail-safe energy supply for injection unit, clamping unit and handling. Quiet, lubrication-free & clean.

Find out more

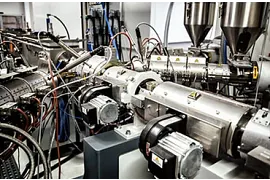

Extrusion machines

Media-resistant and lubrication-free components for downstream equipment, recycling plants, compounders and pelletisers.

Find out more

Blow moulding machines

Fail-safe energy supply systems for measuring systems, winders and so on.

Find out more

Thermoforming machines

e-chains®, cables and bearing technology for thermoformers: temperature-resistant, media-resistant and maintenance-free.

chainge recycling program for energy chains

Do your part to reduce plastic waste in industry:

Send us your discarded plastic energy chains instead of simply disposing of them with other products in industrial waste. The key is that we accept all energy chains, even those from other manufacturers. We then recycle the entries and reward your commitment with an igus® voucher.

More efficient production with the igus sprue picker

To make production more economical, we have developed the low-cost sprue picker: it removes and separates sprues directly from the injection-moulding machine, eliminating costs for subsequent separation and other manual tasks. Our brochure shows how the investment pays off in just a few months, and introduces other automated solutions.

Related industries

Packaging industry

Lubrication-free and low-abrasion components for production lines, including hygenically sensitive ones.

Find out more

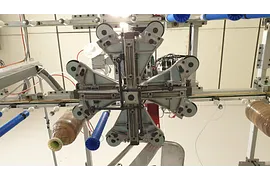

Textile industry

In the textile industry, using lubrication-free and dust-resistant components has top priority.

Find out more