Change Language :

iglidur® J2 - Material data

Material table

General specification

Unit

iglidur® J2

Test method

density

g/cm³

1,44

Colour

light yellow

max. Moisture absorption at 23°C/50% room humidity.

% by weight

0,2

DIN 53495

max. total moisture absorption

wt.-%

1,3

Sliding friction coefficient, dynamic, against steel

µ

0,11 - 0,27

pv value, max. (dry)

MPa x m/s

0,23

Mechanical specification

flexural modulus

MPa

3.605

DIN 53457

flexural strength at 20°C

MPa

101

DIN 53452

Compressive strength

MPa

77

maximum recommended surface pressure (20°C)

MPa

46

Shore D hardness

n.b.

DIN 53505

Physical and thermal specification

Upper long-term application temperature

°C

+90

upper short-term application temperature

°C

+110

Lower application temperature

°C

-50

thermal conductivity

[W/m x K]

0,25

ASTM C 177

coefficient of thermal expansion (at 23°C)

[K-1 x 10-5]

7

DIN 53752

Electrical specification

Volume resistivity

Ωcm

> 1013

DIN IEC 93

surface resistance

Ω

> 1012

DIN 53482

Table 01: Material data

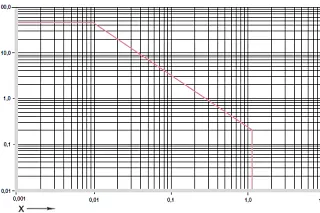

diagram. 01: Permissible pv value for iglidur® J2 plain bearings with 1 mm wall thickness in dry operation against a steel shaft, at +20 °C, installed in a steel housing

X = surface speed [m/s]

Y = load [MPa]

iglidur® J2 is directly comparable with our classic iglidur® J in terms of the general mechanical and thermal specification. However, iglidur® J2 is superior to iglidur® J in terms of mechanical specifications, such as maximum recommended surface pressure. However, the wear resistance in dry operation is inferior.

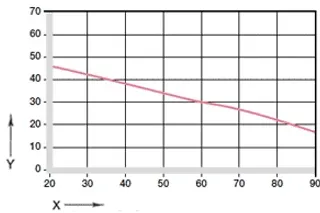

diagram. 02: maximum recommended surface pressure as a function of temperature (46 MPa at +20 °C)

X = temperature [°C]

Y = load [MPa]

Mechanical specification

The compressive strength of iglidur® J2 plain bearings decreases with increasing temperatures. diagram. 02 illustrates this correlation. The maximum recommended surface pressure represents a mechanical material parameter. Conclusions on the tribology cannot be drawn from this.

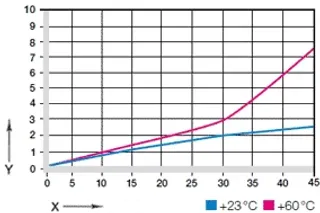

Diagram 03: Deformation under pressure and temperature

X = load [MPa]

Y = Deformation [%]

diagram. 03 shows the elastic deformation of iglidur® J2 under radial load. Possible plastic deformation depends, among other things, on the duration of the load.

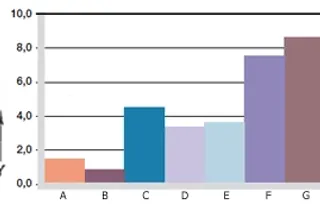

diagram. 06: Wear, rotating application with subdl. shaft materials, p = 1MPa, v = 0.3m/s

X = Shaft material

Y = wear [μm/km]

A = aluminium, hard anodised

B = free cutting steel

C = Cf53

D = Cf53, hard chrome-plated

E = HR carbon steel

F = 304 SS

G = high grade steel

Shaft materials

Friction and wear are also highly dependent on the mating partner. Shafts that are too smooth increase both the coefficient of friction and the wear of the bearing. diagram. 06 shows an extension of the results of tests with different shaft materials. In diagram. 06 it can be seen that iglidur® J2 delivers good wear values in rotation at 1 MPa, especially with free cutting steel. In dry running, the wear values on other shaft materials are significantly higher in some cases.

In contrast to many other iglidur®materials, the wear rate in swivelling is slightly higher compared to rotation with otherwise identical parameters (diagram 07).

Consulting

I look forward to answering your questions

igus Australia1300 726 244Write e-mail

Shipping and consultation

In person:

Monday to Friday from 8 am - 5 pm.