Change Language :

iglidur® F - Material data

Material table

General specification

Unit

iglidur® F

Test method

density

g/cm³

1,25

Colour

black colour

max. Moisture absorption at 23°C/50% room humidity.

% by weight

1,8

DIN 53495

max. total moisture absorption

wt.-%

8,4

Sliding friction coefficient, dynamic, against steel

µ

0,1 - 0,39

pv value, max. (dry)

MPa x m/s

0,34

Mechanical specification

flexural modulus

MPa

11.600

DIN 53457

flexural strength at 20°C

MPa

260

DIN 53452

Compressive strength

MPa

98

maximum recommended surface pressure (20°C)

MPa

105

Shore D hardness

84

DIN 53505

Physical and thermal specification

Upper long-term application temperature

°C

+140

Upper short-term application temperature

°C

+180

Lower application temperature

°C

-40

thermal conductivity

[W/m x K]

0,65

ASTM C 177

coefficient of thermal expansion (at 23°C)

[K-1 x 10-5]

12

DIN 53752

Electrical specification

Volume resistivity

Ωcm

< 103

DIN IEC 93

surface resistance

Ω

< 102

DIN 53482

Table 01: Material data

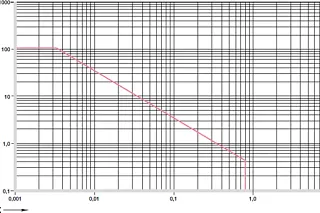

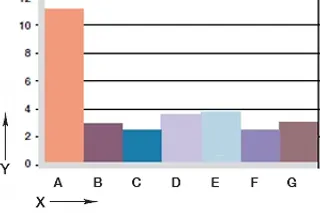

diagram. 01: Permissible pv value for iglidur® F plain bearings with 1 mm wall thickness in dry operation against a steel shaft, at +20 °C, installed in a steel housing

X = surface speed [m/s]

Y = load [MPa]

When plain bearings need to be electrically conductive, especially in applications that should keep out static, iglidur® F is the right choice. Moreover, the iglidur® F plain bearings are extremely pressure-resistant. At room temperature, they could be statically loaded up to 105MPa.

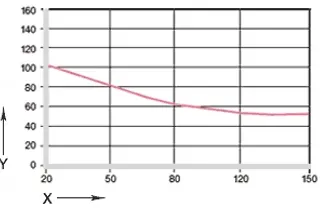

diagram. 02: maximum recommended surface pressure as a function of temperature (105 MPa at +20 °C)

X = temperature [°C]

Y = load [MPa]

Mechanical specification

The maximum recommended surface pressure represents a mechanical material parameter. The compressive strength of iglidur® F plain bearings decreases with increasing temperatures. diagram 02 illustrates this correlation. At the long-term permissible application temperature of +140 °C, the permissible surface pressure is still 50 MPa.

diagram. 03 shows the elastic deformation of iglidur® F under radial load. Under the maximum recommended surface pressure of 105 MPa, the deformation is less than 3.0 %.Plastic deformation can be ignored up to this pressure load. However, it also depends on the duration of the load.

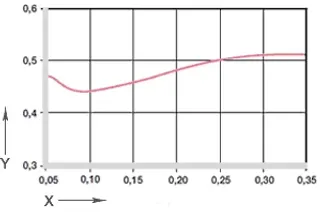

Diagram 04: Coefficient of friction as a function of the surface speed, p = 0.75MPa

X = surface speed [m/s]

Y = coefficient of friction μ

Friction and wear

The coefficients of friction in dry operation are not as favourable with iglidur® F bearings as with various other iglidur® materials. However, iglidur®® bearings can be lubricated without hesitation, and in comparison with lubricated iglidur®® bearings, iglidur®® F bearings achieve excellent results.

Diagram 05: Coefficient of friction as a function of the pressure, v = 0.01m/s

X = load [MPa]

Y = coefficient of friction μ

iglidur® F

Dry

Fat

oil

water

coefficient of friction µ

0,1 - 0,39

0,09

0,04

0,04

Table 04: coefficient of friction for iglidur® F against steel (Ra = 1 μm, 50 HRC)

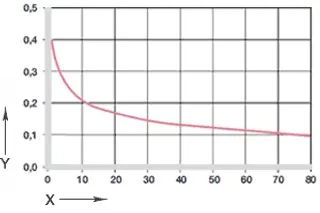

diagram. 06: Wear, rotating application with subdl. shaft materials, p = 1MPa, v = 0.3m/s

X = Shaft material

Y = wear [μm/km]

A = aluminium, hard anodised

B = free cutting steel

C = Cf53

D = Cf53, hard chrome-plated

E = HR carbon steel

F = 304 SS

G = high grade steel

Shaft materials

Diagrams 06 and 07 show an extension of the results of tests with different shaft materials carried out with plain bearings made from iglidur® F. In the lowest load range, the hard-chrome plated shaft proves to be the most favourable mating partner for rotating applications with iglidur® F plain bearings.

Consulting

I look forward to answering your questions

igus Australia1300 726 244Write e-mail

Shipping and consultation

In person:

Monday to Friday from 8 am - 5 pm.