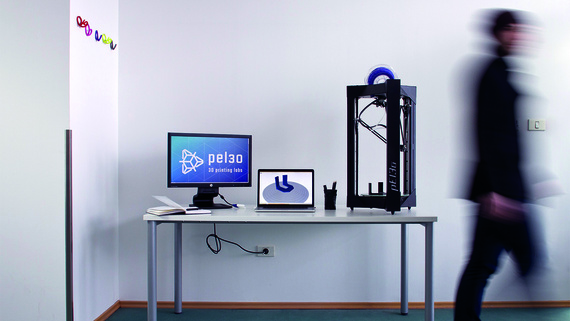

3D printer construction: Lubrication- and maintenance-free products for 3D printers

Components or ready-to-install system solutions for the design of 3D printers – suitable for all installation spaces

Lubrication-free and maintenance-free technologies and components from igus are already playing a central role in most assembly kits and blueprints for 3D printers. Tribologically optimised high-performance polymers ensure enhanced 3D printing technology and lower costs. With its modular motion plastics system, igus enables maximum design freedom for self-constructed 3D printers: drylin linear plain bearings are almost noiseless as no metal bearings are used, and dryspin® lead screw nuts ensure efficient and precise adjustment of the print bed. In addition, energy chains from igus increase machine operating times, as a result of which corkscrews and general cable failures are a thing of the past. Extremely constricted installation spaces, very small bend radii, short assembly times-profit from our wide range of products with no minimum order quantity.Our engineers have developed a high-temperature printer especially for the processing of high-temperature filaments, the design data of which you can download for free and use for building your own high-temperature printer:

Download free design data for the high-temperature 3D printer

Simply order 3D printed components online

Do you require individual, wear-resistant components for building your 3D printer or are looking for solutions for quickly manufacturing abrasion-resistant prototypes or small volumes?Then you can use the igus 3D printing service: simply upload CAD, select material and compare prices right away. The completed parts are ready to ship in one to three days. We also offer 3D printing materials for food contact, ESD protection, fire safety and further special properties.

Find out more about the igus 3D printing service here

Advantages of our products at a glance

- Lubrication-free

- Quiet operation and smooth sliding

- Resistance to dirt

- Long service life

- Corrosion-resistant

- Great variety of materials

Order and test your free sample box now!

Fixed flange bearings for high precision

drylin W360CM

Zero-backlash lead screw nut

Small & spring-loaded miniature guide

drylin T miniature

See all the 2022 news? You can find the overview here.

Especially suitable products for use in 3D printers

- Extensive modular system

- Easy assembly with maximum utilisation of installation space

- Over 25 rail designs for maximum design freedom

Overview drylin W linear guide

- Compatible with standard ball bearings

- Replaceable liners

- Highly wear-resistant, robust and resistant to dirt

Shaft guides drylin R

- Lubrication- and maintenance-free

- Low noise and low vibration

- Media-resistant

Overview lead screw systems

- Versatile use: good combination of high wear resistance, strength and temperature resistance

- Good processing ability with an enclosed printer and igus® adhesive film

Overview print filaments

- Linear bearings in Japan Standard

- Low coefficient of friction

- Very quiet operation

- Dry running

- Robust and reliable

- Secured by circlips

Overview of drylin R plain bearings

- Easy installation

- Minimal inner height (5mm)

- Stable, lightweight for dynamic applications

E2 micro - overview

Application examples of our customers

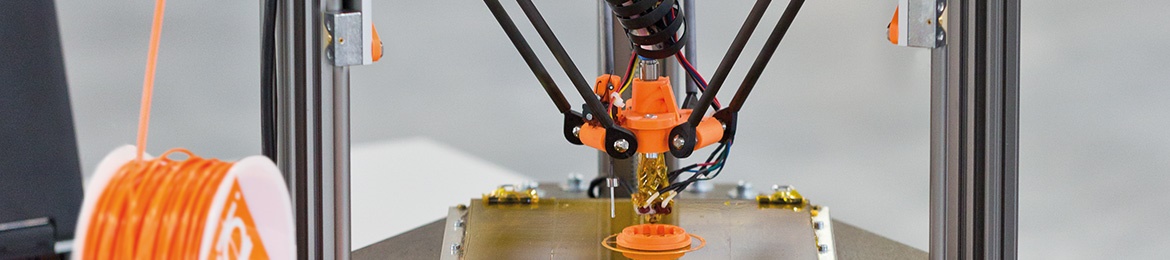

Extreme precision and performance: XXL 3D printer

3D printing and house construction? Do they have anything to do with each other? The example of the Dutch "Europe Building" in the Amsterdam Marine Quarter shows that it works. Our drylin e-linear robots and engineering expertise made this possible.

Learn more about this application

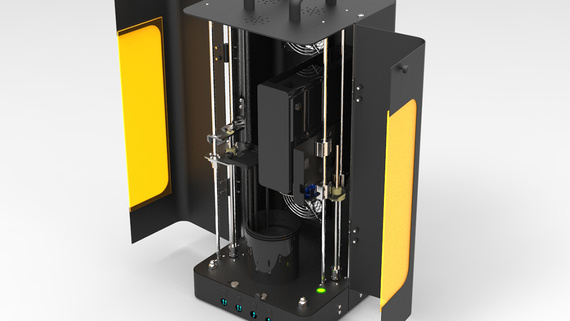

Quick assembly, cost-effective price, high quality

The 3D printer from Cobot impresses not only with its large installation space but also with its innovative design. The few installed parts are fail-safe and give the machine a modular and quickly assembled design. Our drylin linear technology enables completely lubrication-free and maintenance-free operation.

Learn more about this application

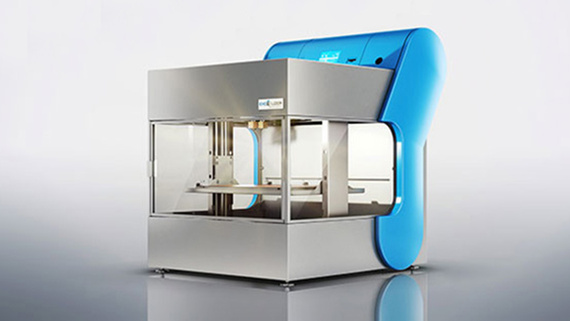

Ready-to-install system solution in 3D printers from EVO tech

Where there is little installation space, space-saving products and cables with tight bend radii are in demand. A completely ready-to-install complete solution consisting of energy chain, cables, drylin linear bearings and motor unit fits into the compact design of this 3D printer from EVO tech GmbH.

Learn more about this application

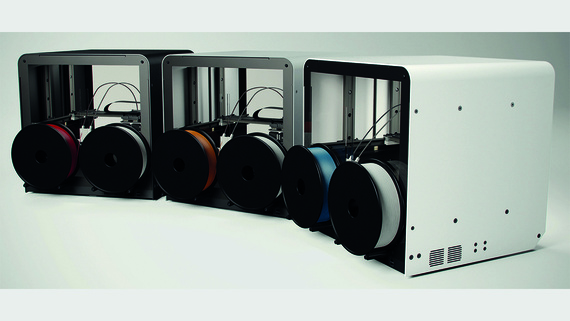

Cost-effective serial printer with high running performance

High running performance, lubrication-free and robust: these are the requirements for linear components in 3D printers. Even in the first serial printer from Kiel-based company Kühling&Kühling, the drylin linear bearings used must withstand high accelerations and temperatures of up to 80°C.

Learn more about this application

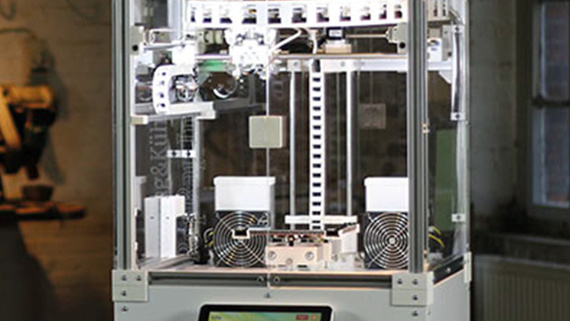

High-performance 3D printer with drylin low profile guides

This 3D printer allows rapid creation of plastic prototypes. The printer is characterised by a high degree of flexibility, which is achieved, among other things, by a print head for two filaments and linear guides with flexible magnetic joints. For fast, low-noise and precise movements, the developers relied on our drylin linear guides and carriages.

Learn more about this application

3D printer for metal parts: precision at 150°C and dust

This laser-based 3D printing machine creates custom metal parts from titanium, aluminium, steel, or even gold. The printing process requires maximum precision when applying metal powder layers at high temperatures. For this reason, the manufacturer relies on a drylin linear guide system.

Learn more about this application

Compact and cost-effective 3D resin printer

The central element of a 3D DLP resin printer is the Z axis motion system. A solution was sought here that guarantees high accuracy and is cost-effective.

Our iglidur bearings and drylin linear guides ensure, among other things, smooth movement of the pressure carriage and a minimum print resolution of 37.5 micrometres.

Our iglidur bearings and drylin linear guides ensure, among other things, smooth movement of the pressure carriage and a minimum print resolution of 37.5 micrometres.

Learn more about this application

Further information

Related websites

Printing technology

Insensitive to pressure dust and paper dust.Printing technology

Vending machinery

Product solutions for vending machine technology: 100% lubrication-free; quiet, dependable with a long service lifeVending machinery