Maintenance-free for quiet, continuous

operation in vending machines

The possible uses of automatic machines have become more diverse and with increasing mechanisation, many more innovations can be expected. Vending machines, for example, are no longer merely used to sell things, they also serve as advertising surfaces and can gather user data for monitoring purposes. They have long been a part of everyday life and, in most cases, are hardly noticeable any more. Above all when they work reliably and without problems. Bearings and gears in payment systems, shelves that can be pulled out with linear guides, electric linear systems that move scanners or product dispensers, energy chains that carry cables: all these components are expected to meet high requirements with regard not only to their performance but also to their design and they are often in use around the clock. Our maintenance-free, high-performance polymers ensure that vending machines, which are expected to work autonomously, are not permanently dependent on maintenance assistance from us human beings.

Benefits of igus products:

- Maintenance-free

- Cost-effective

- Save installation space and weight

- Easy assembly

- Complete systems or individual components from batch size 1

- Service life calculation

- Low noise and low vibration

Vending machines

Linear and plain bearing technology, energy chains, gears, and gearbox solutions for maintenance-free, durable, cost-effective vending machines.

Discover now

Automation solutions in the catering industry

Robotics solutions, bearing technology, and e-chains for fast, maintenance-free, economical automation of services in restaurants and cafés.

Discover now

Lubrication-free, low-maintenance, durable

components in coffee machines

components in coffee machines

Discover them now

Continuously expandable drive axis

drylin GRW

Rust-proof angular gearbox with lightweight housing

Angular gearbox

SCARA robot with four degrees of freedom

SCARA robot

See all the 2022 news? You can find the overview here.

Free white paper:

Linear robot system for maintenance-free 24/7 operation

"Build or buy": Tips on designing vending machinesVending machines are in vogue. The manufacturer must decide how the products are stored, presented, and made available to the buyer – and how to design the inner workings of the movable product dispenser. One option is lift systems combined with preconfigured linear robots, but there are others. The white paper outlines what is possible and what the designer should consider during project planning to achieve the right vending machine for a given application.

Download now

Free samples – as a box or individually for your application

See for yourself the quality of our motion plastics- Order a free motion plastics sample box with our most important products and information about various vending machine applications.

- The box is not specific enough? We will find the right product for your application and send you an individual sample free of charge.

Order now

Selected motion plastics for the vending machine industry

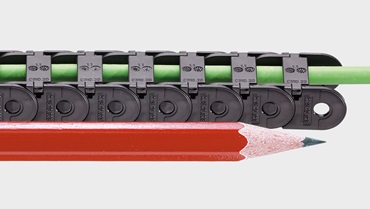

E2 micro e-chains

For the smallest of installation spaces

UL94-V2 (optional V0)

Stable, light and quiet

To product overview E2 micro

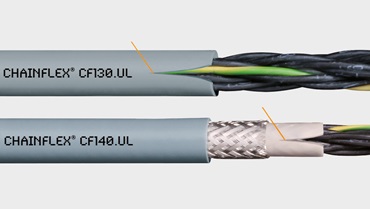

chainflex CF130.UL & CF140.UL

PVC outer jacket (CF140 shielded)

For medium-duty applications

Flame-retardant

Buy chainflex control cables now

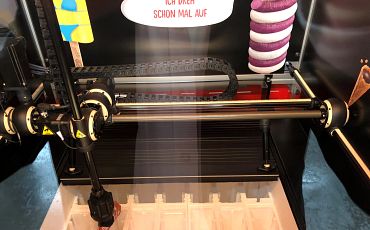

drylin E single axes with a motor

Easy installation

Proximity switch mounting by means of T slot

Everything from one source, readily assembled and tested

More information about drylin E linear axes

drylin N low-profile linear guides

Very lightweight

Low installation height 6-12mm

Numerous carriage options

Go to drylin low-profile linear guide shop

drylin lead screw technology

Lubrication-free and maintenance-free

Low noise and low vibration

Media-resistant

Go to drylin lead screw technology shop

Security gates reliably moved

Raising and lowering the facial recognition display, swinging the barrier back and forth and extending and retracting it – our products, which require no lubrication or maintenance, ensure trouble-free movement in airport security gates.

► Harnessed readychain e-chains and drylin e-drive technology for display movement

► igubal pillow block bearings for barriers that swing back and forth

► igubal rod ends for retracting and extending barriers

► Harnessed readychain e-chains and drylin e-drive technology for display movement

► igubal pillow block bearings for barriers that swing back and forth

► igubal rod ends for retracting and extending barriers

Successful in use in vending machine technology

Lubrication- and maintenance-free components for the autonomous robo kitchen

Healthy fast food prepared and served by a cooking robot: for their autonomous robo kitchen, the designers at the Canadian start-up RoboEatz were looking for components that are suitable for food processing and as cost-saving as they are durable and low-maintenance. Energy supply systems, various bearings and drive components from igus are the perfect solution here...Learn more

Durable and low-maintenance: Apiro gearbox solution in an ice cream vending machine

The sec°mat IC One, made by Bochum-based Seco Manufaktur, turns the serving of ice cream and the sales process into an event. Modular Apiro robot kinematics not only ensure long-lasting, low-maintenance operation of the vending machine, but also that special wow effect for users ...Learn more

... other success stories

Drive systems and energy supply systems in bar robots, linear robots in WC cassette cleaning machines, and guide systems in coffee machines: Discover more applications from our customers in the vending machine industry, where our motion plastics are demonstrating their advantages.Discover now

Tested in the test laboratory for use in the real world

All products are tested for wear and load capacity under real-life conditions in the igus test laboratory, the largest in the industry. The results are incorporated into our service life calculation tools and allow exact durability predictions.Upon request, igus carries out customer tests to check product use under completely customised conditions.

More about the igus test laboratory

The huge motion plastics sample box

Trying things out made easy: with the igus corner, you always have the most recent motion plastics suited to your individual industry sector at hand.We will bring the display to you, assemble it upon request and fill the compartments with the products of your choice. Or you can set it up yourself. As a permanent exhibition or for a limited period of time.

Order now for free

What are the most important regulations for food sector vending machine manufacturers? How can installation space be saved in the face of a growing product range? The igus blog features interesting articles on vending machine technology.

Take a look now!