Change Language :

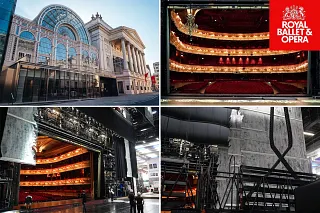

25 years of loyal service to London's Royal Opera House

When retrofitting the lighting trusses, the famous theatre once again relies on zig-zag systems

It is one of igus' stage engineering milestones and favourite projects: in 1999, the Royal Ballet and Opera in London commissioned igus to equip the lighting trusses in the upper machinery with a space-saving, durable energy supply. The solution is a customised zig-zag e-chain system that has been in service for over 25 years without failure. When the theatre modernised its lighting in 2025, it also needed a new energy supply system that had to meet new requirements in terms of load, smooth running and weight. The igus team worked on and delivered a modern zig-zag generation before the start of the 2025/26 season, which from then on contributed to the smooth running of every performance as a silent helper.

Profile

- What was needed: New energy supply system including cables for the new LED stage lighting.

- Requirements: Space-saving design, stability and durability, lightweight (<150 kg), smooth running, minimum maintenance requirements.

- Industry: Stage technology, stage machinery.

- Success for the customer: With the new zig-zag system, the Royal Ballet and Opera has an energy supply that is not only reliable and familiar, but has also been perfectly adapted to the high loads in daily theatre operations. igus supplied a completely pre-fitted system consisting of box, e-chains and cables, which could be installed immediately and offers maximum operational reliability. This ensures that the lighting technology remains strong and trouble-free in use over the long term. At the same time, recycling the old energy chains via the igus Chainge recycling programme improves the company's sustainability balance.

Featured key products

Royal Opera House background

This is what it looks like when you look up from behind the stage curtain: Five new lighting hoists, equipped with LED spotlights, can be raised to a height of up to 25 metres.

Each row contains three adjacent truss units. They each consist of a lower truss with the lights and a main truss into which the new zig-zag energy supply systems are integrated.

Two reverse e-chains per unit prevent the system from swaying too much. Two guide boxes with one chain each are installed on the centre unit, while two chains fold compactly into a single box on the shorter side units.

Around 9 tonnes of energy chains with a total length of over 1km are installed in the lighting hoists. The chains contain robust chainflex motor, bus, data, fibre optic and control cables that can reliably withstand continuous movements over many years.

20 zig-zag systems consisting of guide box, e-chains and flexible chainflex cables were delivered from Cologne to the Royal Ballet and Opera in London - each as a complete unit ready for installation.

Recycled instead of thrown away: the discarded energy chains - around 2.4 tonnes of material - have found their way into the recycling loop via the igus Chainge programme.

Recommended for you

Consulting

I look forward to answering your questions

igus Australia1300 726 244Write e-mail

Shipping and consultation

In person:

Monday to Friday from 8 am - 5 pm.