Change Language :

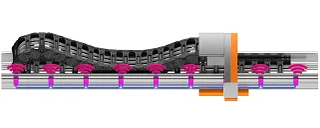

Energy chains for overhead gantry cranes

Overhead gantry cranes have been designed for the overhead moving of loads within a building, such as in production and assembly areas. As they are fixed to the building, they allow for three directions of movement, which guides cables, hoses and energy supplies. The aim is to minimise downtime and maintenance and maximise the system's function. This is not only due to economic aspects, but also with regard to occupational safety. Due to the individual building conditions and areas of application, gantry cranes are usually custom-made.

Our energy supply systems have been developed for different operating conditions. They are designed in an optimal way, as a complete system or individual components, and can be offered with a predictable service life.

Would you like more information about the e-chains® used on overhead gantry cranes? Our experts will be happy to get in touch with you.

EC.PP trough-integrated path measurement system

The quick and easy to install position measuring system for every type of crane. Provide your crane with millimetre-accurate positioning and also create the possibility of integrating other smart plastics products, which further increases the safety and performance of the system.

Products for overhead gantry cranes

Easy and quick to install

White paper: efficient energy supply systems for cranes in steel plants

Modern steel production takes place in steel plants with increasingly high levels of integration. What technical challenges result from this for the transport and conveyor plant used, especially for the cranes in steel plants? How can an energy supply be achieved that is both reliable and efficient? There are two options: festoons and energy chains. What system has more advantages?

Successful application stories with overhead gantry cranes

Consulting

I look forward to answering your questions

igus Australia1300 726 244Write e-mail

Shipping and consultation

In person:

Monday to Friday from 8 am - 5 pm.