Change Language :

igus bearing technology

No lubrication, no maintenance

What do our iglidur ® plain bearings, xiros ball bearings, igubal ® spherical plain bearings and iglidur ® PRT slewing ring bearings have in common?

Compared to pure metal bearings, they are up to 80% lighter, vibration-damping, maintenance-free and self-lubricating. This not only saves time and money, but also protects the environment.

A study by RWTH Aachen University is the first to show the enormous savings potential of self-lubricating plastic bearings in terms of lubricant, labour and maintenance costs.

Discover our product range and benefit from the unique specifications of our bearing products!

Our bearing technology with high-performance polymers

igubal®

Self-adjusting, low-wear and dirt-resistant spherical plain bearings

Spherical bearings

xiros

Corrosion-resistant, low-noise and optionally non-magnetic ball bearings

ball bearings

iglidur®

Bearings in various types, materials and in more than 10,000 sizes

Plain bearings

iglidur® PRT

Robust, lightweight and cost-effective slewing ring bearings for precise rotary movements

PRT slewing ring bearings

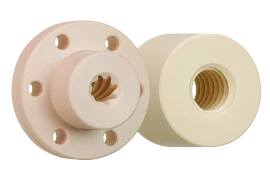

dryspin®

Lubrication- and maintenance-free lead screw technology in various sizes, pitches and types

lead screw technology

drylin®

Linear rails for various applications and industries

Success stories: lubrication-free bearings save time and money

Many well-known companies have already been able to save time and money by using our lubrication-free bearings. Krones AG, for example, saves over €50 and 13 hours of maintenance time per year by using one plastic plain bearing per labelling station. Heineken Brasil uses self-lubricating igus® bearing technology in conveyor belts, thereby increasing reliability and minimising downtime. Rockinger uses a self-lubricating wear insert in the KS80 ball coupling, which eliminates the need for lubrication and reduces maintenance work to a minimum, and Lemken, which specialises in the manufacture of agricultural machinery for soil cultivation, sowing and crop protection, saves 22 lubrication points per cultivator.

Heineken Brasil

Savings with 600 storage locations:

£2,815.49 Costs¹

1,560 h maintenance²

180.08 kg CO2 equivalent³

Rockinger

Savings per trailer coupling:

£87.36 costs¹

13 h maintenance²

1.4 kg CO2 equivalent³

Lemken

Savings per cultivator:

£88 Costs¹

14.7 h maintenance²

6.3 kg CO2 equivalent³

1Annualcost savings through the use of plastic plain bearings per machine/system

2Annualtime savings through the use of plastic plain bearings per machine/system

3Annualsaving of CO2 equivalents through the use of plastic plain bearings per machine/system

Why do our bearings work without lubrication?

The savings potential of igubal spherical insert bearings

| Cost savings with 200 pieces | ||

|---|---|---|

| Spherical ball | igubal JEM | |

| Costs for 200 pieces | £1,350 | £300 |

| Estimated service life | 1 year | 4 years |

| Costs for lubricants (per year) | £45 | £0 |

| Hourly time required for lubrication (every year): 3 min. per bearing x 24 times every year x 200 bearings | 240hrs | 0hrs |

| Hourly rate per employee (€30/hr) x lubrication (240hrs) | £7,200 | £0 |

| Total annual costs | £8,595 | £75 |

| Annual savings | £8,520 |

white paper

The advantages of the lubrication-free bearing arrangement of our plain, ball and PRT slewing ring bearings