xiros® plastic ball bearings: applications, development and tests

The product range of xiros plastic ball bearings comprises a large number of different product variants. What they all have in common is that they do not require any additional lubrication. This results in considerable advantages, since lubricants are prevented from contaminating the environment, being washed out or decomposing due to external influences in every application.

There are additional advantages, depending on the type of construction:

There are additional advantages, depending on the type of construction:

- Maintenance-free

- Lightweight

- Non-metallic (due to the use of glass and polymer balls)

- Non-magnetic

- Resistant to chemicals

- Corrosion-resistant

- Electrically insulating

- FDA-compliant

- Predictable service life

Application areas

In contrast to metal ball bearings, xiros polymer ball bearings can be used completely without lubrication. They are therefore suitable for a wide range of special applications in which, compared to permanently lubricated metallic ball bearings, maximum speeds or loads are not important, but lubrication-free use is. These are e.g. the food, packaging and medical device, packaging and textile industries or even the chemical industry and cleanroom applications as well as electronics and office equipment. Applications also result from the absence of metals and the specification of being non-magnetic. These are primarily applications in medical devices and measurement equipment.Customer applications with xiros polymer ball bearings

Competitive comparison: igus vs. competitors' material counterparts

Numerous tests and material developments have enabled the materials of the raceways to be continuously improved. As a result, plastic ball bearings could be developed that allow higher speeds, more loads and longer service life. But development continues: we still do not consider the issue of plastic ball bearings to be exhausted by a long way. We know that with our many years of experience in tribologically-optimised plastics and our testing capabilities, we can continue to advance xiros ball bearings. As a result of our special compound and injection moulding manufacturing process, we can guarantee a significantly longer service life for your application compared to our competitors.In the xiros test laboratory, our ball bearings are tested for service life and wear. In addition to the actual material comparison, tests indicate these experiments also answer questions about the impact of external influences such as temperature, humidity or dust.

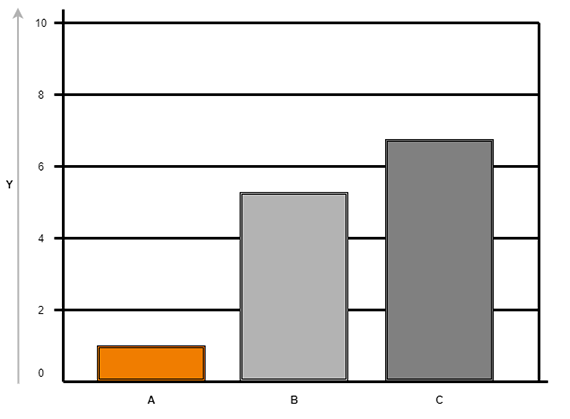

Polymer ball bearings: all-rounder material

Y = Wear [μm / 1 million rpm]

A = xirodur B180

B = Alternative polymer ball bearing I

C = Alternative polymer ball bearing II

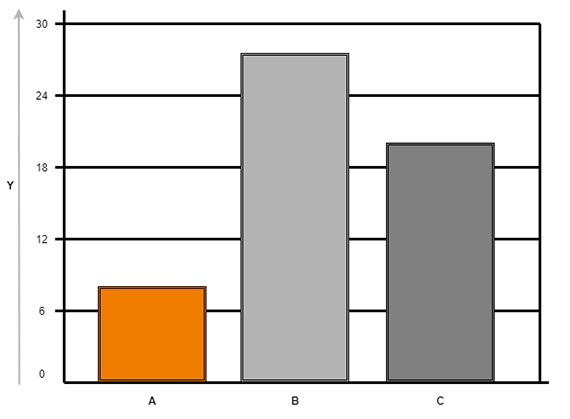

Polymer ball bearings: high-temperature material

Y = Wear [μm / 1 million rpm]

A = xirodur A500

B = Alternative high-temperature ball bearing I

C = Alternative high-temperature ball bearing II