Change Language :

Ball screw drive vs dryspin lead screw drive

Maintenance-free even with short strokes

Product range

Can a plastic threaded nut withstand high static loads?

The new type of the DST-JGRM series with its injection moulding-optimised design is the robust alternative to a flanged threaded nut. The special type enables easy assembly and, in particular, the absorption of radial loads. In combination with a stainless steel plate, it can withstand axial loads of up to 6MPa trade show.

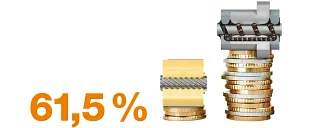

How can I reduce costs by 61.5 %?

Our dryspin® plastic threaded nuts not only stand out from their metal counterparts due to their technical advantages, but also impress when it comes to acquisition costs. They are up to 61.5 % cheaper to purchase than conventional metal lead screw nuts. The costs are also significantly reduced over the course of the application. Maintenance costs and the purchase of external lubricants are completely eliminated with dryspin® lead screw technology.

100% lubrication-free

maintenance-free dry operation thanks to drylin® lead screw technology

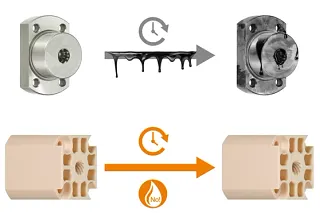

Lubrication is essential for metal lead screw nuts, otherwise metallic abrasion will occur. The abrasion can block the entire system and quickly bring the application to a standstill without appropriate maintenance. The lubrication- and maintenance-free drylin® thread systems are the perfect alternative to conventional metal screw drives.

maintenance-free dry operation thanks to drylin® lead screw technology

With our drylin® lead screw nut made from iglidur® high-performance polymers, you don't need a single drop of lubricant. The self-lubricating effect minimises maintenance. Particles such as dust and fibres can adhere much less easily due to the dry operation. This leads to a significant increase in service life in dirty environments compared to conventional, lubricated solutions.

Robust and with known connection dimensions

Up to 34.4 % weight saving

Recirculating ball screw nut with flange vs. drylin® trapezoidal lead screw nut with flange (identical dimensions)

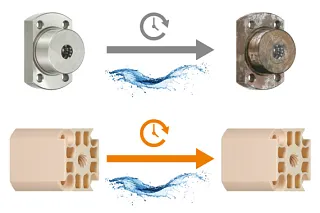

100% corrosion-free

Regular maintenance work due to corrosion?

As soon as metal ball screw nuts are used in a damp environment, they start to corrode after a short time. The rust impedes smooth running and the screw drives have to be regularly serviced or replaced. This in turn saves time and money.

The dryspin® technology gives rust no chance

The drylin® lead screw technology, on the other hand, is completely corrosion-free. This means that the drylin® lead screws always maintain their smooth running and long service life, even when used in corrosive environments - and are completely maintenance-free. All our plastic nuts are made from the tribologically optimised iglidur® high-performance polymers. The matching threaded spindles are made exclusively from stainless material.

Quiet operation with vibration dampening

Advantages and disadvantages

Consulting

I look forward to answering your questions

igus Australia1300 726 244Write e-mail

Shipping and consultation

In person:

Monday to Friday from 8 am - 5 pm.